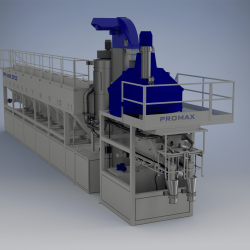

All around the world PROMAX will top the standards in the technology of thermoplastic production. The PROMAX thermoplastic manufacturing plants are developed and designed to meet the utmost requirements for environmental safety as well as top-level production capacity.

PROMAX has over 30 years of business experience in the field; this experience helped us in developing and improving the PROMAX CF03 Thermoplastic Production Plant, which has been setting new and higher standards for thermoplastic production.

PROMAX CF03 is a new generation of thermoplastic manufacturing plants for road marking material. The plants are built in a module system which gives us the possibility to construct the plant and put it into operation in as little as 5 working days.

The plants can be installed even in the smallest manufacturing facilities thanks to their compact and efficient module design. Electric power is the only external facility which is required to put the plant into function with full production capacity.

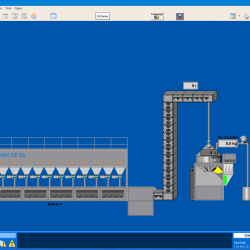

In order to ensure a stable production of more than 500 various thermoplastic compounds, the plant can be supplied with the most modern batch production control and registration system. PROMAX can also offer the entire range of services for thermoplastic production:

- Project management

- Site management solutions

- Quality control and development

This new and successful product gives our customers the possibility of a consistent and fast return of the investment and the possibility to fully control the quality of the thermoplastic compounds and the production development. Since 2005 PROMAX has supplied the CF03 thermoplastic production plant to customers in Belarus, Sweden, Portugal, Qatar, USA, Russia, South Korea, India and others.